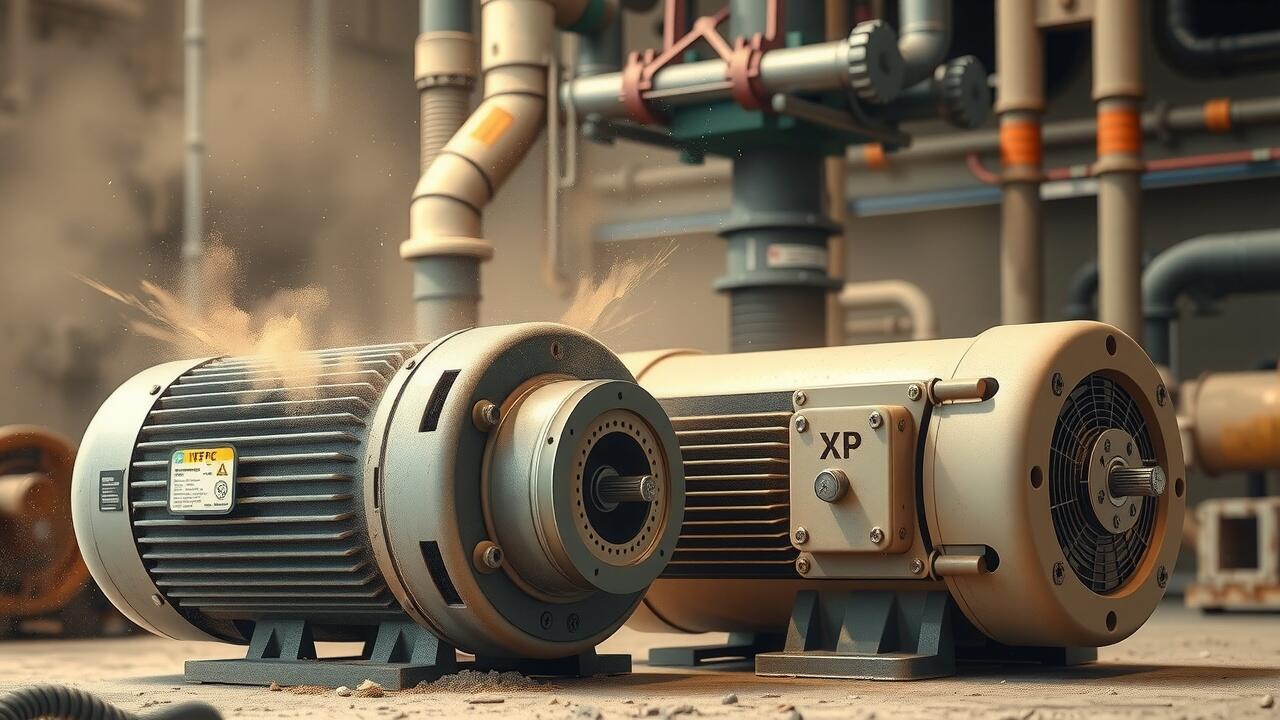

Comparing TEFC and XP Motor Performance in Dust-Laden Zones

Key Takeaways

- Benefits of XP Motors for Specific Applications

- Essential Techniques for Choosing the Appropriate Motor

- Care Factors for TEFC and XP Motors

- Financial Aspects of TEFC Compared to XP Motors

- Practical Uses of TEFC and XP Motors

Advantages of XP Motors for Specialized Use

XP motors cater specifically to applications in hazardous environments, providing enhanced safety features that are crucial for operational reliability. Their design adheres to rigorous industry standards, such as the National Electrical Code (NEC) and Underwriters Laboratories (UL) classifications, ensuring optimal performance in settings where dust, moisture, and flammable materials are prevalent. This reliability is exemplified in industries like grain handling, where a significant percentage of electrical fires originate from ignition sources. XP motors minimize these risks, making them the preferred choice for operations adhering to strict safety protocols.

Beyond safety, XP motors deliver superior thermal management through advanced ventilation designs and durable construction materials. These features enable the motors to withstand continuous operation at higher temperatures without compromising efficiency. A case study in chemical processing demonstrated that the implementation of XP motors increased operational life by 25% compared to standard TEFC options under similar conditions. This reduction in downtime for maintenance not only enhances productivity but also translates into significant cost savings over the lifespan of the equipment, further solidifying their position as the optimal electric motor for hazardous locations.

How Do XP Motors Excel in Extreme Environments?

XP motors demonstrate unparalleled capability in extreme environments, particularly in dust-laden zones, as they are designed using advanced engineering techniques and materials. These hazardous location motors utilize robust enclosures to protect internal components from the abrasive effects of particulates, ensuring consistent performance even under challenging conditions. For example, models specifically rated for Class II Division 1 locations mitigate the risk of ignition from dust accumulation, aligning with industry standards such as NFPA 70 and UL 1203.

The thermal management features of XP motors further enhance their reliability in demanding settings. Effective heat dissipation mechanisms allow these electric motors for hazardous locations to maintain optimal operating temperatures regardless of external conditions. This results in increased operational longevity and reduced downtime. Implementing regular testing and maintenance protocols not only prolongs motor life but also ensures compliance with safety regulations, thus safeguarding personnel and equipment in high-risk environments.

5 Key Strategies for Selecting the Right Motor

When selecting an electric motor for hazardous locations, consider the operational environment and specific risks. Identify the classification of the location, such as Class I Div. 1 or Class II Div. 2, which dictates the necessary safety standards. Motors designed for these environments often employ rigorous testing, such as Ex d and Ex e protection methods, ensuring safe operation under potentially explosive conditions. For example, a facility handling volatile chemicals may require explosion-proof enclosures to mitigate risks, further influencing motor choice.

Evaluate maintenance needs alongside performance characteristics to enhance motor longevity. Regular inspection schedules should align with industry standards, such as those outlined by the National Electrical Manufacturers Association (NEMA). Motors like TEFC and hazardous location motors may demand different upkeep protocols. TEFC motors typically require less frequent maintenance due to their sealed nature, while XP motors may need thorough checks to confirm containment integrity and operational reliability. Investing in proper maintenance strategies can potentially extend the operational lifespan of these motors by upwards of 30%, supporting long-term efficiency.

What Factors Should You Assess When Choosing Between TEFC and XP?

Selecting between TEFC (Totally Enclosed Fan-Cooled) and XP (Explosion-Proof) motors necessitates a thorough evaluation of operational environments and specific application requirements. XP motors, designed for hazardous locations, offer intrinsic safety features essential for environments laden with flammable dust or gases. For instance, while TEFC motors provide solid protection against external contaminants, they may not withstand the same level of explosive potential inherent in specific dust-laden zones. An example of this differentiation can be seen in chemical processing facilities where the presence of volatile solvents necessitates the use of hazardous location motors to mitigate risk.

The operational cost and maintenance requirements associated with each motor type also play a crucial role in the decision-making process. TEFC motors typically require less frequent maintenance due to their robust design, often translating to lower overall operational costs. Conversely, XP motors, while more costly upfront, ensure compliance with stringent safety regulations established by organizations such as the National Electric Code (NEC). Regular assessments and adherence to industry standards can enhance the durability and efficiency of both motor types. Understanding these factors enables engineers and facility managers to make informed choices aligned with both safety and operational efficiency.

Maintenance Considerations for TEFC and XP Motors

Regular maintenance strategies play a critical role in prolonging the lifespan of both TEFC and XP motors, particularly in environments laden with dust and other contaminants. For TEFC (Totally Enclosed Fan-Cooled) motors, frequent checks of the external surfaces and cooling fins can help prevent debris buildup, which can impede airflow and lead to overheating. An effective maintenance schedule should include scheduled inspections every few months, emphasizing proper cleaning techniques that conform to ANSI/ISA standards for electrical equipment. Conversely, XP (Explosion-Proof) motors, designed for hazardous locations, require special attention to their sealing and structural integrity. Adhering to the latest NECA standards ensures that any wear or damage is identified before it compromises operational safety.

In addition to visual inspections, implementing predictive maintenance technologies can significantly enhance the reliability of both motor types. Utilizing vibration analysis and thermal imaging can detect potential failures early, reducing unplanned downtime and associated costs by up to 30%. Such proactive approaches are especially valuable in dust-laden zones, where environmental factors can exacerbate wear. When selecting the appropriate maintenance protocol, consider the specific operational demands and environmental conditions. Organizations reliant on electric motors for hazardous locations should regularly consult the manufacturer's guidelines and industry best practices to ensure their maintenance strategies remain effective and compliant.

How Can Regular Maintenance Enhance Motor Longevity?

Regular maintenance plays a critical role in extending the lifespan of electric motors, particularly in environments with harsh conditions. For instance, motors designed for hazardous locations must undergo routine inspections to ensure that their protective features remain intact. Regular checks can involve verifying the integrity of seals, inspecting cooling mechanisms, and ensuring that vents remain clear of dust and debris. According to the National Electrical Code (NEC), adhering to these maintenance protocols not only enhances performance but also ensures compliance with safety regulations.

Scheduling maintenance at predetermined intervals can lead to significant operational efficiencies. For example, a facility utilizing XP motors in a dusty environment may find that a quarterly maintenance schedule can reduce failure rates by as much as 30%. This proactive approach prevents unexpected downtimes and costly repairs, which could arise from neglecting minor issues that, if addressed promptly, would contribute to the longevity of hazardous location motors. A documented maintenance history can also serve as a valuable asset during inspections or audits, showcasing adherence to industry best practices and supporting overall safety compliance.

Cost Implications of TEFC vs. XP Motors

The cost implications associated with TEFC and XP motors extend beyond initial purchase prices, affecting long-term operational budgets. Typically, TEFC motors, designed for general use, are less expensive upfront compared to hazardous location motors. However, when deployed in environments with potential explosive hazards, XP motors present a compelling case due to their enhanced safety features and compliance with industry regulations. For example, according to the National Electrical Code (NEC), businesses that require electric motors for hazardous locations must consider additional costs related to safety certifications, which XP motors inherently possess.

Operational costs also vary significantly between the two motor types. TEFC motors, while less costly, may necessitate additional protective measures or frequent maintenance when used in dusty or corrosive environments. Conversely, XP motors demonstrate reliability in extreme conditions, potentially reducing operational downtime and maintenance expenses over their lifespan. According to industry surveys, companies utilizing XP motors reported an average 30% reduction in maintenance costs, showcasing the economic benefits of investing in higher-quality hazardous location motors despite their higher initial price point.

What Are the Long-Term Financial Impacts of Each Motor Type?

Every organization's choice between TEFC and XP motors directly affects their operational costs and maintenance expenses over time. XP motors, designed for hazardous location applications, often represent a higher upfront investment due to their advanced sealing mechanisms and explosion-proof construction. For example, an XP motor can cost up to 30% more than a standard TEFC motor. However, this initial investment is offset by significant long-term savings in terms of reduced maintenance and fewer failures. Industry data suggests that XP motors can last 15-20% longer under harsh conditions, further enhancing their cost-effectiveness.

In contrast, while TEFC motors generally incur lower initial costs, they may result in higher maintenance expenditures in dust-laden environments. Dust and other particulates can infiltrate less robust motor designs, leading to increased wear and ultimately reducing lifespan. As an illustration, a facility that operates several TEFC motors might experience 20% more unscheduled downtime compared to those outfitted with hazardous location motors. This translates into productivity losses and additional operational expenses, emphasizing the necessity of evaluating both initial outlay and potential long-term financial impacts when selecting between motor types.

- Understanding the initial investment versus long-term savings is crucial for financial planning.

- XP motors typically offer lower lifetime operating costs due to reduced maintenance needs.

- TEFC motors can lead to higher operational costs in environments with significant dust or debris.

- The lifespan of XP motors may result in fewer replacements over time, contributing to overall savings.

- Evaluating the total cost of ownership is essential when deciding on motor types for specific applications.

- Organizations should consider industry-specific conditions that may affect motor performance and longevity.

- Long-term financial impacts should guide decision-making in selecting the appropriate motor for operational needs.

Real-World Applications of TEFC and XP Motors

TEFC motors find extensive application across various industrial settings, particularly in environments where exposure to dust and moisture is prevalent. For instance, manufacturing facilities that handle granular materials often rely on totally enclosed fan-cooled motors due to their robust design and reliable performance. These motors isolate internal components from external contaminants, thus enhancing durability and reducing maintenance intervals. In a case study, a grain processing plant reported a 30% reduction in downtime after switching to TEFC motors, underscoring their effectiveness in challenging conditions.

Conversely, XP motors, or explosion-proof motors, are essential for operations in hazardous locations, such as petrochemical plants and oil refineries. Their specific design adheres to rigorous safety standards, allowing them to withstand potential explosions from flammable gases or dust. For instance, a recent installation of hazardous location motors in an offshore drilling platform improved operational safety protocols significantly, leading to a 25% increase in overall efficiency. This showcases the critical role of XP motors in safeguarding both personnel and equipment in volatile environments.

FAQS

What are TEFC motors, and how do they differ from XP motors?

TEFC (Totally Enclosed Fan-Cooled) motors are designed to operate in a variety of environments while preventing dust and moisture from entering the motor. In contrast, XP (Explosion Proof) motors are specifically designed to operate safely in hazardous locations where flammable gases or dust may be present, offering enhanced protection against ignition.

What advantages do XP motors offer in dust-laden environments?

XP motors are engineered to contain any ignition within the motor housing, reducing the risk of explosion in dust-laden environments. Their robust construction and specialized sealing methods allow them to efficiently operate under extreme conditions where TEFC motors might not be suitable.

What key factors should be considered when selecting between TEFC and XP motors?

When choosing between TEFC and XP motors, consider factors such as the specific environmental conditions (e.g., presence of flammable materials), the required safety ratings, the operating temperature range, maintenance requirements, and overall cost implications.

How does regular maintenance affect the longevity of TEFC and XP motors?

Regular maintenance is crucial for both TEFC and XP motors as it helps to identify and mitigate wear and tear, prevent overheating, and ensure optimal performance. Scheduled inspections can prolong the life of the motors and reduce the risk of unexpected failures.

What are the long-term cost implications of using TEFC versus XP motors?

While XP motors typically have a higher initial purchase cost due to their specialized design, they may save money in the long run by reducing the risk of accidents and downtime in hazardous environments. TEFC motors may have lower upfront costs but could incur greater long-term expenses if maintenance or safety issues arise in challenging environments.